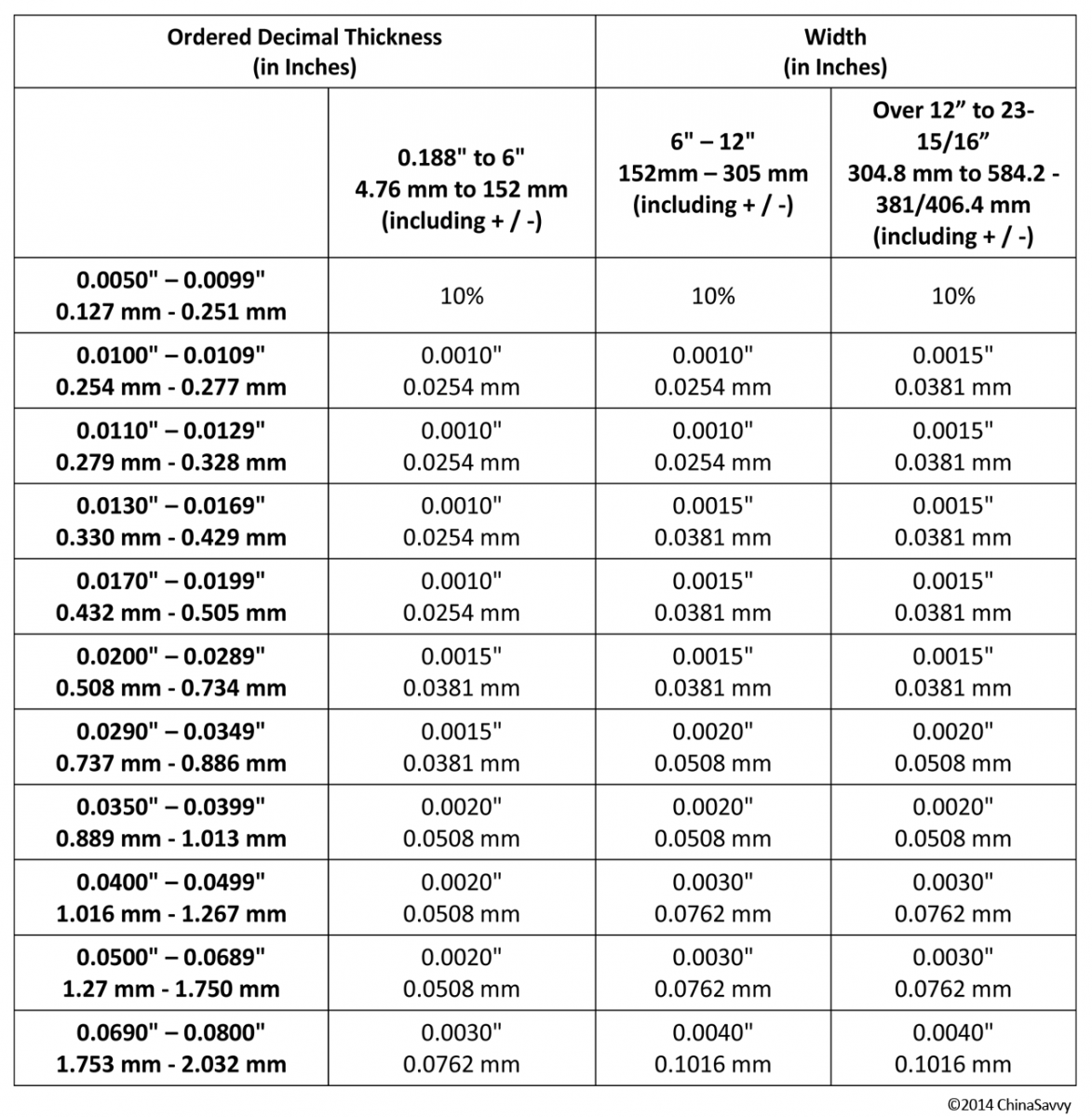

Sheet Metal Thickness Tolerance - 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. Factors like bend radius and feature. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges.

During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Factors like bend radius and feature. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from.

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. Factors like bend radius and feature.

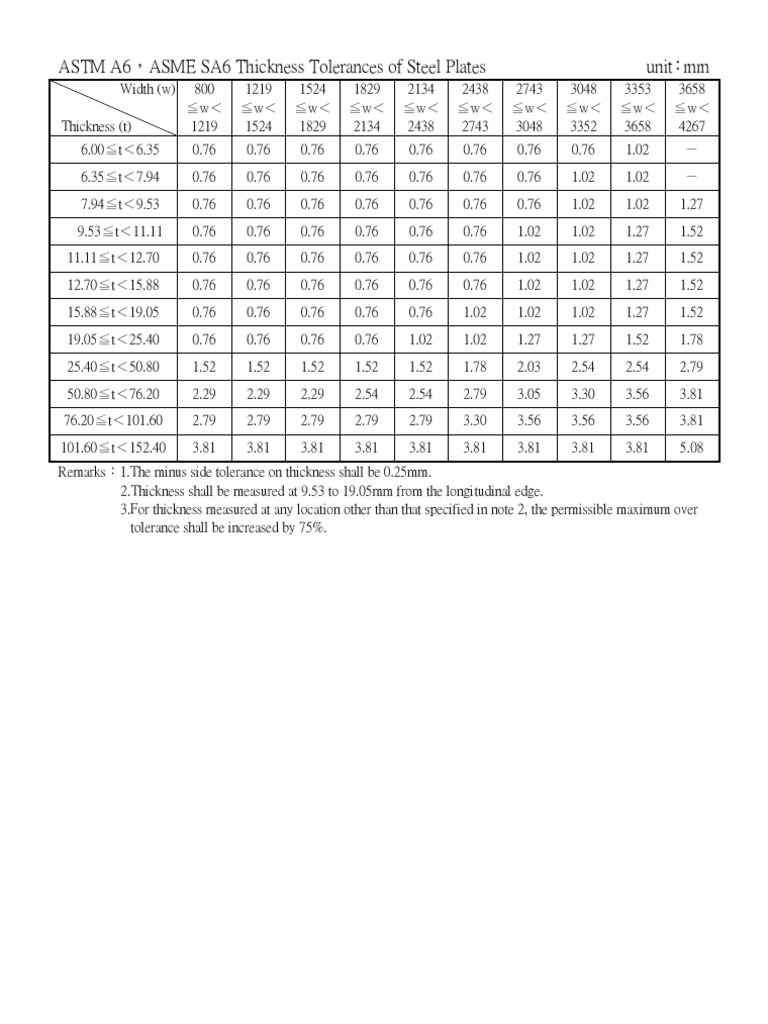

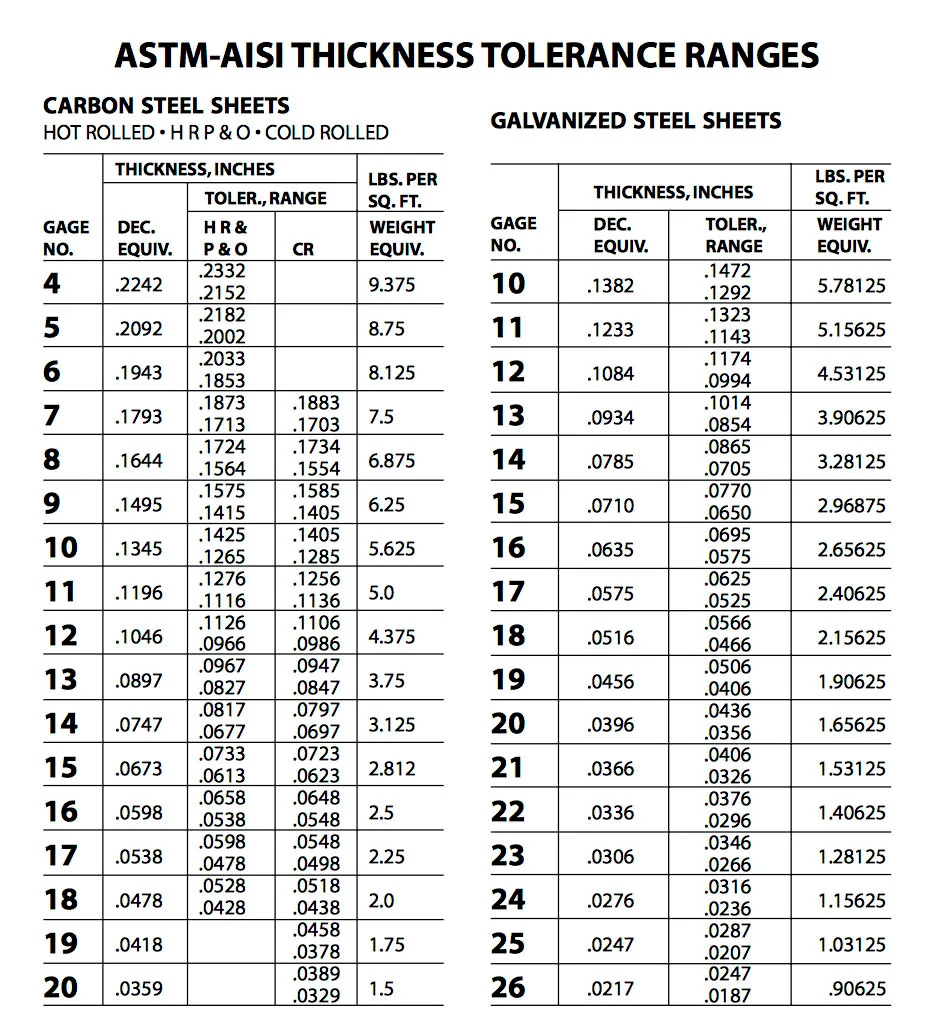

ASTM A6 ASME SA6 Thickness Tolerances of Steel Plates

Factors like bend radius and feature. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner.

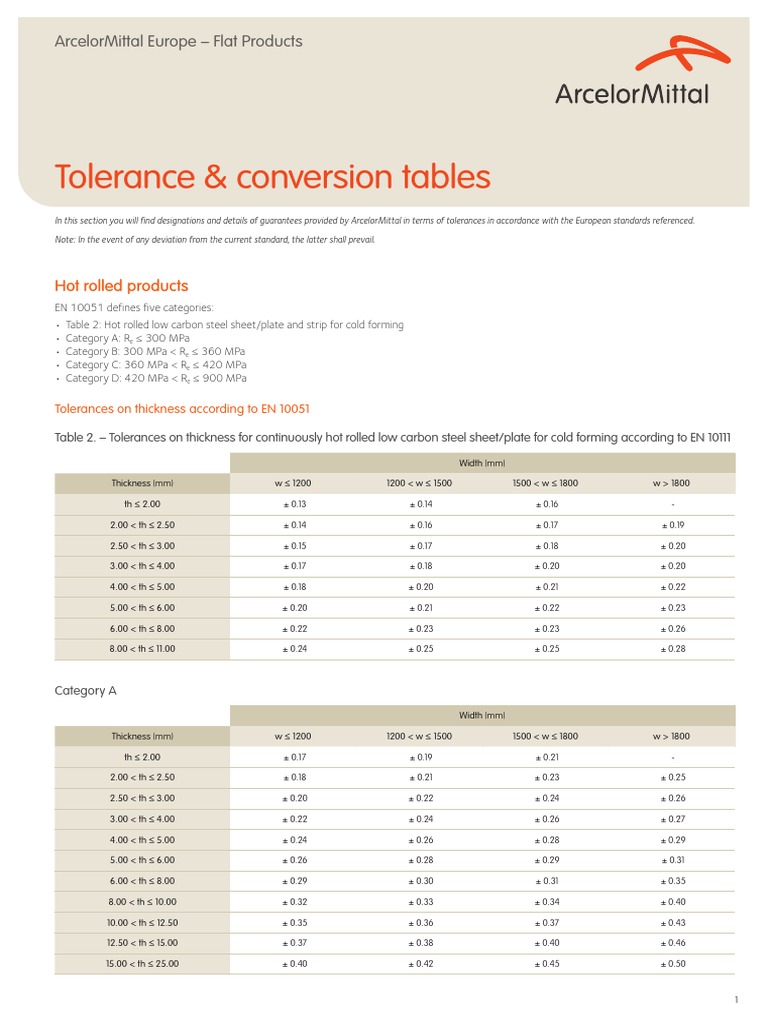

(PDF) Steel Sheet Thickness Tolerance DOKUMEN.TIPS

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. Factors like bend radius and feature. During the rolling process the rollers bow slightly, which results in the sheets being thinner.

Sheet Metal Thickness Standard Tolerances at Roosevelt Gabriel blog

38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Factors like bend radius and feature. Because parts are formed from a single sheet of metal, designs must maintain.

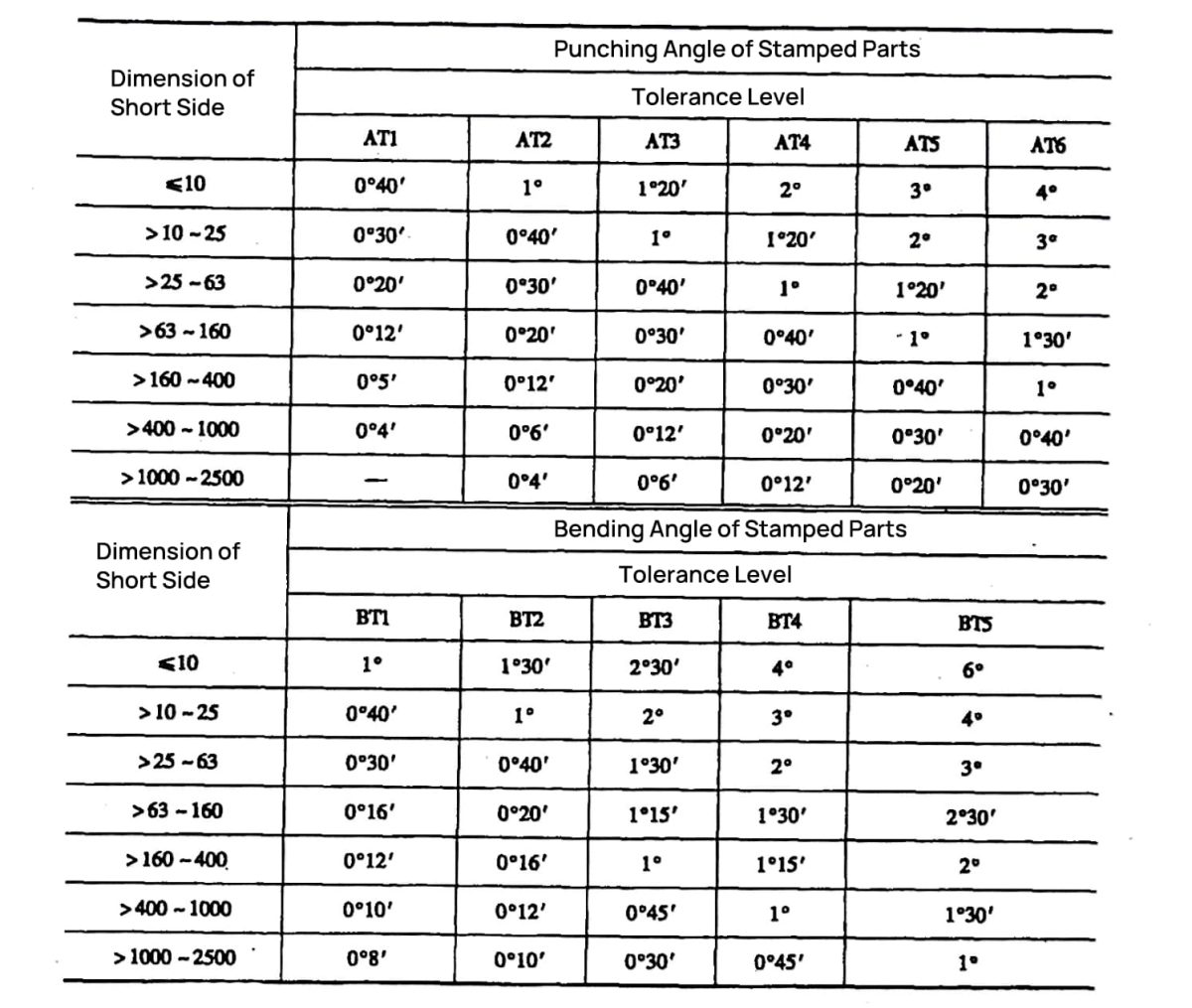

Sheet Metal Tolerances The Key to Precision Engineering MachineMFG

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a.

Sheet Metal Thickness Tolerances Engineering Tolerance Foot (Unit)

Factors like bend radius and feature. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a.

Snless Steel Thickness Chart Bios Pics

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Factors like bend.

Steel Gauge Chart MD Metals

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Factors like bend radius and feature. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a.

Metric Sheet Metal Thickness Chart

38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Factors like bend.

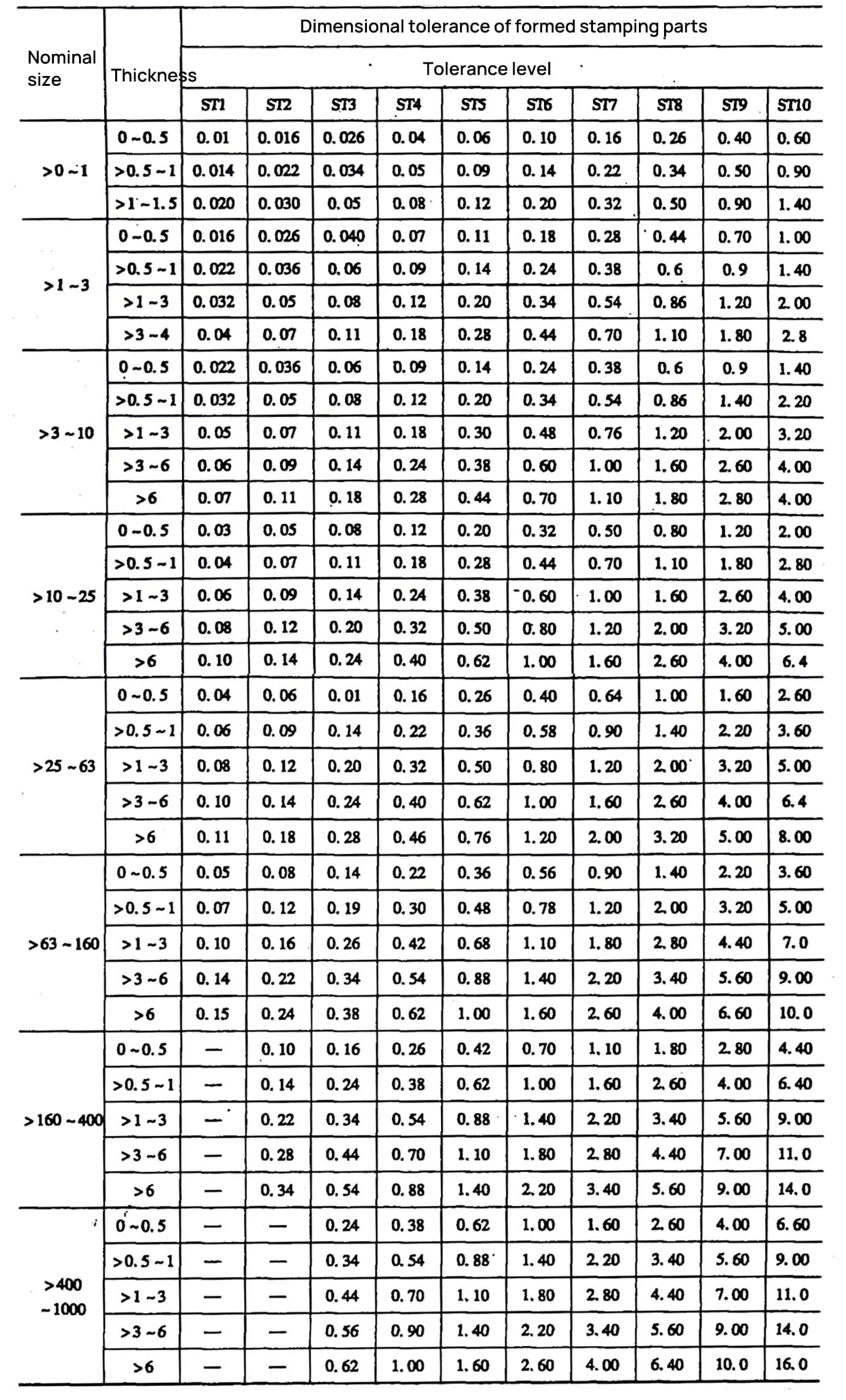

Sheet Metal Tolerances The Key to Precision Engineering MachineMFG

Factors like bend radius and feature. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Because parts are formed from a single sheet of metal, designs must maintain.

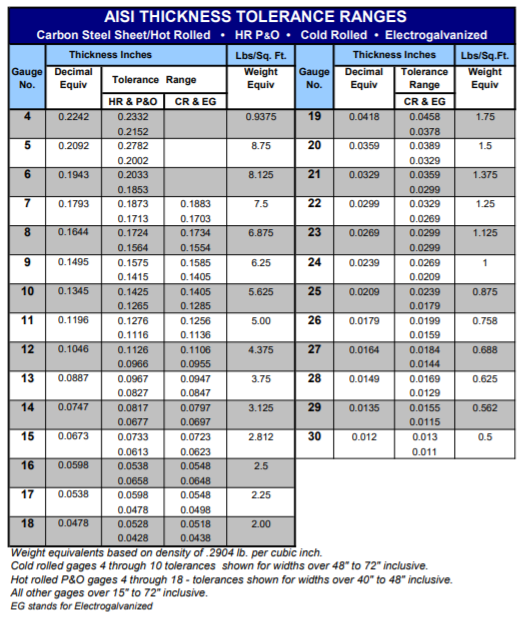

ASTMAISI Thickness Tolerance Ranges Conklin Metal Industries

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. 38 rows the chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a.

38 Rows The Chart Below Can Be Used To Determine The Equivalent Sheet Thickness, In Inches Or Millimeters, For A Gauge Number From.

During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature.